Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

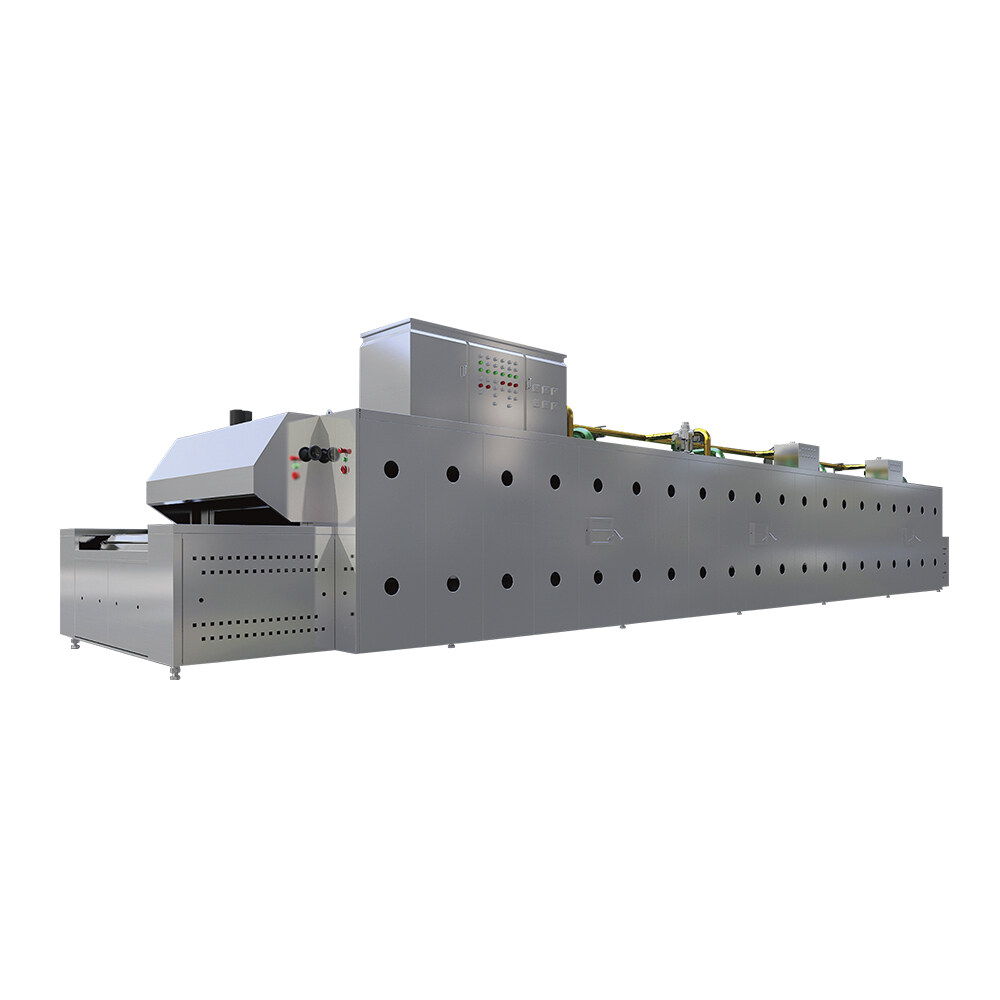

In the world of large-scale baking and food production, efficiency and consistency are key to success. This is where the tunnel oven becomes an invaluable asset. Designed to handle high volumes of product with uniform results, tunnel ovens are the workhorses of the baking industry. Let’s delve into the world of tunnel ovens and discover how they can transform the baking process.

What is a Tunnel Oven?

A tunnel oven is a type of industrial oven that is characterized by its elongated, tunnel-like baking chamber. Products enter the oven on one end, are baked as they travel through the tunnel on a conveyor belt, and emerge perfectly cooked on the other end. The continuous nature of a tunnel oven makes it ideal for operations that require a consistent output of baked goods.

The Advantages of Using a Tunnel Oven

The primary advantage of a tunnel oven is its ability to maintain a consistent baking temperature throughout the length of the tunnel, ensuring that each product is baked uniformly. This level of consistency is difficult to achieve with traditional batch ovens, especially when dealing with large quantities. Additionally, tunnel ovens are designed to be energy efficient, often incorporating heat recovery systems that reduce overall energy consumption.

Customization and Versatility

Tunnel ovens can be customized to meet the specific needs of a production line. They can be designed to accommodate different heating methods, such as direct gas-fired, indirect gas-fired, electric, or a combination of these. The conveyor speed, temperature zones, and humidity levels can all be adjusted to suit the type of product being baked, whether it’s bread, pastries, pizzas, or cookies.

The Role of Tunnel Ovens in Automation

Automation is becoming increasingly important in the food production industry, and tunnel ovens fit perfectly into automated workflows. By integrating with automated dough handling and loading systems, tunnel ovens can help streamline the entire baking process, from mixing to packaging. This integration not only boosts productivity but also reduces labor costs and the potential for human error.

Scalability for Growing Businesses

For businesses looking to scale up their production, a tunnel oven offers a clear path to increased output. Unlike batch ovens, which have a fixed capacity, tunnel ovens can handle a continuous flow of products, making it easier to ramp up production in response to growing demand. This scalability is a significant factor for businesses planning for long-term growth.

Maintaining a Tunnel Oven

While tunnel ovens are designed for durability and long-term use, regular maintenance is essential to keep them operating at peak efficiency. This includes routine cleaning of the conveyor belt and baking chamber, as well as inspections and servicing of heating elements and other critical components. A well-maintained tunnel oven can provide years of reliable service.

Conclusion

The tunnel oven is a cornerstone of modern baking operations, offering unparalleled efficiency, consistency, and scalability. Its ability to integrate into automated systems and its customizable nature make it a versatile solution for a wide range of baking applications. Whether you’re running a small bakery ready to expand or a large food production facility seeking to optimize your processes, a tunnel oven is a smart investment that can help you achieve your business goals. As the demand for baked goods continues to rise, the tunnel oven will remain an essential tool for meeting the needs of a hungry market.